Hoe hoogwaardige plafondventilatoren de temperatuurregeling in werkplaatsen verbeteren

Thermische stratificatie in industriële werkplaatsen begrijpen

Warme lucht heeft de neiging om naar het plafond te stijgen in grote industriële ruimtes, waardoor koelere lucht beneden blijft waar mensen daadwerkelijk werken. Dit gebeurt omdat warme lucht lichter is dan koude lucht, wat leidt tot zogenaamde thermische laagvorming. Het resultaat? Onregelmatige temperaturen doorheen deze ruimtes. Werknemers bevriezen vaak op vloerniveau, terwijl al die dure energie verloren gaat aan het verwarmen van lege ruimte boven hen. Volgens onderzoek dat vorig jaar werd gepubliceerd door de Industrial Ventilation Association kan dit temperatuurverschil tot wel 15 graden Fahrenheit bedragen tussen vloer en plafond in hoge werkplaatsomgevingen. Best aanzienlijk als je bedenkt hoeveel energie op deze manier verloren gaat.

Hoe plafondventilatoren temperatuurlagen verminderen en een gelijkmatige warmteverdeling bevorderen

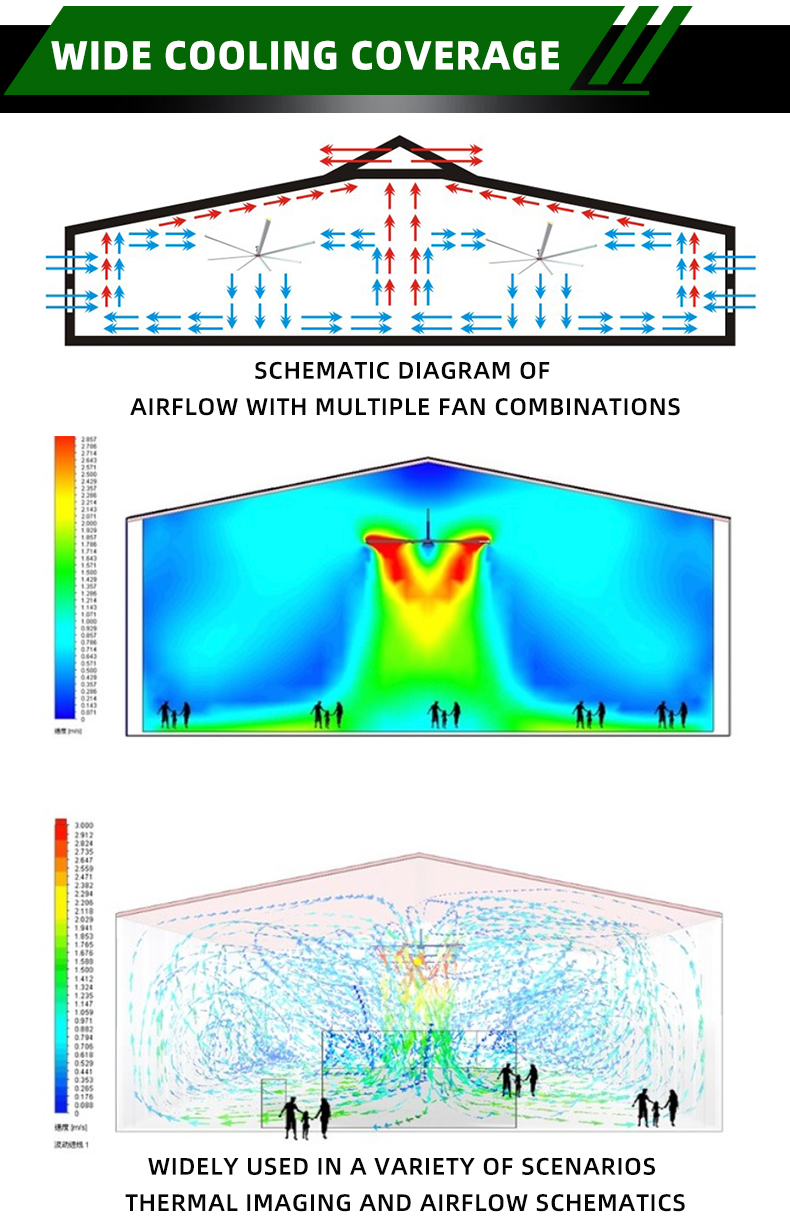

Grote plafondventilatoren verstoren de luchtlagen door lucht verticaal te bewegen zonder grote turbulentie te veroorzaken. Deze ventilatoren hebben doorgaans enorme bladen die tussen de 2,4 en 7,3 meter breed zijn en langzaam grote hoeveelheden lucht verplaatsen, waardoor warme en koele luchtlagen worden gemengd zonder ongemakkelijke tocht te veroorzaken. Wanneer deze ventilatoren de dode punten waar de lucht stilstaat elimineren, zorgen ze voor een vrijwel gelijkmatige temperatuur in elke ruimte of het hele gebouw waar ze in zijn geïnstalleerd. Bedrijven die HVLS-ventilatoren in hun ruimtes hebben geïnstalleerd, zien ook indrukwekkende resultaten. Velen melden dat de bedrijfstijd van hun verwarmings- en koelsystemen met 15% tot 30% is gereduceerd, simpelweg omdat de temperatuur veel beter over het gehele oppervlak wordt verdeeld.

Casestudy: metalen fabriekshal van 929 m² bereikt verlaging van 6°F

Een metaalwerkplaats in het Middenwesten installeerde 3 HVLS-plafondventilatoren om onevenmatige koeling aan te pakken. Gegevens na installatie toonden:

- verlaging van 6°F in gemiddelde vloer-plafond temperatuurvariatie

- 22% minder energieverbruik voor airco tijdens piekuren in de zomer

- Minder klachten van werknemers over 'hot spots' bij lasstations

Dit komt overeen met de bevindingen uit het Industriële Decarbonisatieverslag van het Ministerie van Energie uit 2022 , waarin luchtstroombeheer wordt benadrukt als een belangrijke strategie voor energiezuinige klimaatregeling in productieomgevingen.

Energie-efficiëntie en kostenbesparingen met HVLS-plafondventilatoren

HVLS-ventilatoren versus traditionele HVAC: vergelijking van energieverbruik en efficiëntie

HVLS-plafondventilatoren kunnen daadwerkelijk 8 tot 10 keer meer lucht verplaatsen per watt vergeleken met reguliere koelsystemen. Bekijk de cijfers: standaard HVAC-systemen hebben tussen de 7 en 10 kilowatt nodig om een oppervlakte van ongeveer 10.000 vierkante voet af te koelen. Ondertussen doen grote HVLS-ventilatoren hetzelfde werk met slechts 1,5 tot 2 kilowatt. Dat betekent een elektriciteitsbesparing van ongeveer driekwart. Waarom gebeurt dit? Het heeft alles te maken met de speciaal gevormde bladen. Deze creëren een gelijkmatige luchtstroom die zich uitstrekt over een gebied van wel 200 voet breed. Deze dekking maakt hen veel efficiënter voor grote open ruimtes zoals magazijnen of sporthallen.

Data-inzicht: 30% lagere koelenergiegebruik in magazijnomgevingen

Een analyse uit 2025 van 47 industriële installaties toonde aan dat pakhuizen die HVLS-waaier gebruiken, de koelkosten in de zomer met 30% verminderen ten opzichte van uitsluitend HVAC-gebruik. Door luchtstromingen van 4–6 mph te creëren, kunnen de temperatuurinstellingen met 4°F worden verhoogd terwijl het comfort voor aanwezigen behouden blijft—een energiebesparing van 12% per graad volgens ASHRAE-normen.

Vermindering van de belasting op HVAC-systemen en langdurige operationele kosten

HVLS-waaiers verlengen de levensduur van HVAC-apparatuur doordat de compressorloopduur met 40–60% wordt verminderd in hybride systemen. Installaties melden:

| Onderhoudsmetrie | Alleen HVAC | HVAC + HVLS |

|---|---|---|

| Filtervervangingen/jaar | 8 | 5 |

| Compressorreparaties/5 jaar | 3.2 | 1.1 |

| Nabijvullen koelmiddel/jaar | $920 | $310 |

Deze synergie vermindert de kosten voor klimaatbeheersing jaarlijks met 18–22% in productieomgevingen.

ROI-analyse: Teruggewinningsperiode voor HVLS-ventilatorinstallaties in industriële omgevingen

De meeste bedrijven recupereren de investering in HVLS-systemen binnen 14–26 maanden alleen al door energiebesparingen. Een casestudy uit 2024 toonde aan dat een assemblagefabriek van 50.000 vierkante voet behaalde:

- Aanvankelijke kosten : €28.500 (6 ventilatoren + installatie)

- Jaarlijkse besparing : €19.200 energie / €6.400 onderhoud

- Amortiseringsperiode : 17 maanden

Na terugverdiening levert het systeem €25.600 aan jaarlijkse besparingen op—een ROI van 79% over 10 jaar.

Verbetering van luchtkwaliteit en werknemerscomfort in industriële werkplaatsen

Verbetering van de binnentemperatuur via constante luchtcirculatie

Luchtkwaliteit blijft een echt probleem in de meeste industriële werkplaatsen waar machinale bewerkingen fijne deeltjes veroorzaken en chemische dampen in de lucht hangen. Het installeren van plafondventilatoren met een hoog debiet maakt echter een groot verschil. Deze ventilatoren doorbreken het laagvormingseffect dat optreedt wanneer warme lucht opstijgt, waardoor verse lucht continu wordt gecirculeerd in de ruimte. Volgens recente studies uit het Industrial Ventilation Report van vorig jaar, vermindert dit soort opstelling de hoeveelheid zwevende verontreinigingen met ongeveer 28% in vergelijking met ruimtes zonder adequate ventilatie. Wanneer de lucht met ongeveer 3 tot 5 mijl per uur stroomt over de werkplaatsgebieden, voorkomt dit dat schadelijke stoffen zich op de lange termijn ophopen. Bovendien helpt het bedrijven om te voldoen aan de OSHA-richtlijnen voor werknemersveiligheid, wat altijd een zorg is voor fabrieksmanagers die de gezondheid van hun medewerkers belangrijk vinden.

Het verband tussen luchtcirculatie, thermisch comfort en productiviteitswinst

Thermische regulatie heeft direct invloed op de productiviteit van werknemers. Wanneer de omgevingstemperatuur boven de 82°F komt, daalt de productiviteit met 2% per extra graad. Plafondventilatoren verminderen warmtebelasting door verdampingskoeling en behouden 95% van de basisproductiviteit in metaalbewerkende omgevingen. Uit een ergonomiestudie uit 2023 bleek dat geoptimaliseerde luchtstroompatronen vermoeidheidsgerelateerde fouten tijdens achturen met 19% verminderen.

Casestudy: Verhoogde productie in een autoreparatiebedrijf na installatie

Een autoreparatiewerkplaats in het Middenwesten installeerde 12 plafondventilatoren met grote diameter (24-ft spanwijdte, 1,5 RPM) en noteerde meetbare verbeteringen:

| METRISCH | Voorinstallatie | Post-Installatie | Verandering |

|---|---|---|---|

| Boxbenutting | 68% | 82% | +14% |

| Verftekortkomingen | 11,2% | 7,1% | -37% |

| Dagelijks afgesloten werkbonnen | 43 | 51 | +19% |

Verbeterde luchtcirculatie verlaagde de stilstand van de spuitcabine met 22 uur per maand en elimineerde seizoensgebonden temperatuurklachten van monteurs.

Optimale plaatsing en afmeting voor maximale effectiviteit van plafondventilatoren

De juiste plafondventilator kiezen op basis van de afmetingen van de werkplaats

Het kiezen van de juiste maat plafondventilator maakt een groot verschil voor hoe goed de lucht in een ruimte circuleert. Kleine werkplaatsen van minder dan 1000 vierkante voet werken meestal goed met ventilatoren tussen de 36 en 48 inch doorsnede. Maar grotere ruimtes, bijvoorbeeld meer dan 10.000 vierkante voet, hebben die grote HVLS-ventilatoren nodig die van 8 tot maar liefst 24 voet breed kunnen zijn. Recente sectoronderzoeken toonden iets interessants aan: wanneer mensen ventilatoren installeren die te klein zijn voor hun ruimte, verbruiken ze ongeveer 28% meer energie omdat het systeem langer en intensiever moet draaien om het verschil te compenseren. Probeer altijd de ventilatorbladen af te stemmen op de werkelijke grootte van de ruimte. Geluk het of niet, soms werkt het plaatsen van meerdere kleinere ventilatoren verspreid over een langwerpige rechthoekige ruimte beter dan één grote ventilator. De meerdere units helpen de lucht naar waar hij heen moet duwen, in plaats van stilstaande luchthoeveelheden in de hoeken achter te laten.

Beste praktijken voor montagehoogte en afstand in hoge zalen

Voor ruimtes met plafonds tussen de 15 en 30 voet, installeer ventilatoren op ongeveer 10 tot 15 voet boven de grond. Bij plafonds hoger dan 30 voet zijn verlengde downrods nodig om de lucht goed in beweging te houden. Zorg ervoor dat er minstens 1,5 keer de ventilatordiameter aan open ruimte is tussen de ventilator en muren of obstakels. Dit helpt turbulentie te voorkomen, wat een veelgemaakte fout is en kan leiden tot een efficiëntieverlies van ongeveer 40 procent, zoals blijkt uit diverse HVAC-beoordelingen door de jaren heen. In magazijnen of andere high-bay omgevingen is afstand houden ook cruciaal. De vuistregel is om ventilatoren op ongeveer 1,25 keer de hoogte van het plafond van elkaar te plaatsen. Dit creëert het gewenste gelijkmatige luchtpatroon zonder warme plekken of dode zones.

Laminaire Luchtpatronen Ontwerpen en Dode Zones Elimineren

Het vinden van de juiste plekken voor ventilatoren helpt om die vervelende luchtzakken te verminderen waar stof en warmte zich ophopen, wat ook wat druk van het verwarmings- en koelsysteem neemt. Wanneer u ventilatoren instelt, richt u ze zo dat ze lucht blazen naar waar machines warmte genereren of waar werknemers het grootste deel van hun tijd doorbrengen. Dit zorgt voor een betere luchtstroom in de ruimte. Voor winkels vol met grote apparatuur die paden blokkeren, tonen studies met computermodellen aan dat er iets interessants gebeurt wanneer ventilatoren om de 15 graden in hoeken worden geplaatst in plaats van recht in een rij. Het bereik springt met ongeveer 35%. Het combineren van bovenluchtsventilatoren met op muren gemonteerde inlaatluchten maakt ook een groot verschil. Metalenfabrieken melden dat de temperatuur fluctuaties vrij stabiel blijven, meestal niet meer dan 2 graden Fahrenheit verschil tussen verschillende gebieden van de werkplaats.

Belangrijk overweging : Pilotproeven van ventilatorplaatsen via tijdelijke bevestigingen vóór permanente installatie voorkomen kostbare herpositionering. Inrichtingen die deze aanpak toepassen, rapporteren een 22% hogere ROI op de koelinfrastructuur.

Slimme installatie, onderhoud en duurzaamheid

Installatie van beste praktijken voor industriële plafondventilatorsystemen

Goed installeren begint met het laten controleren van de bouwstructuur. Er moet worden uitgezocht wat de veilige gewichtslimieten zijn en waar precies alles moet komen te zitten. De meeste mensen ervaren dat ventilatoren hangen op een hoogte tussen de 12 en 18 voet het beste werkt voor een goede luchtcirculatie, zonder een struikelgevaar te vormen in die hoge werkplaatsen. Probeer de ventilatoren uit te lijnen met de bestaande HVAC-ventilatieroosters in de ruimte. Dit helpt ervoor te zorgen dat de lucht goed stroomt over het gehele gebied. Ook is het belangrijk om te controleren of de bestaande bedrading voldoende is voor de stroombehoefte van deze grotere motoren. Grote fabrikanten raden meestal aan om grotere plafondventilatoren op ongeveer 20 tot 30 voet afstand van elkaar te plaatsen bij zeer grote gebouwen (alles boven de 30.000 vierkante voet). Deze afstand helpt om vervelende plekken zonder luchtcirculatie te voorkomen.

Regelmatig onderhoud voor duurzaam presteren en betrouwbaarheid

Kwartaalonderhoud en schoonmaak voorkomen stofophoping op de bladen, wat de luchtdoorstroming tot wel 25% kan verminderen. Smeer jaarlijks de lagers en controleer de motoruitlijning om slijtage door trillingen te minimaliseren. Voorspellende onderhoudsprogramma's met behulp van trillingsensoren hebben onverwachte stilstand in industriële omgevingen met 40% verlaagd.

Slimme bediening en automatisering in moderne plafondventilatorbediening

IoT-ingeschakelde systemen synchroniseren ventilatorsnelheden met realtime temperatuurgegevens, waardoor energieverlies tijdens piekuren wordt verminderd. Installaties die gebruikmaken van geautomatiseerde planning via mobiele apps rapporteren 18% lagere jaarlijkse koelkosten in vergelijking met handmatige bediening.

Duurzaamheid en ESG-voordelen van energiezuinige plafondventilatoroplossingen

HVLS-ventilatoren verlagen de afhankelijkheid van HVAC-systemen en verminderen CO₂-uitstoot met gemiddeld 1,2 ton per ventilator per jaar. Een Industrial Electrification Report uit 2023 benadrukt hoe deze systemen fabrikanten helpen ESG-doelstellingen te bereiken, terwijl ze een 25–35% sneller rendement op investering realiseren dan traditionele koelverbeteringen.

Veelgestelde vragen

Wat zijn HVLS-plafondventilatoren en hoe verschillen ze van gewone plafondventilatoren?

HVLS (High-Volume, Low-Speed) plafondventilatoren hebben grote bladen die variëren van ongeveer 8 tot 24 voet in doorsnede. Deze ventilatoren verplaatsen meer lucht bij lagere snelheden, waardoor een constante luchtcirculatie ontstaat in grote ruimtes zoals magazijnen, in tegenstelling tot gewone ventilatoren die kleinere bladen hebben en lucht sneller verplaatsen maar minder oppervlak bestrijken.

Hoeveel kunnen HVLS-plafondventilatoren besparen op energiekosten?

HVLS-ventilatoren kunnen het energieverbruik aanzienlijk verminderen, waarbij het stroomverbruik ongeveer driekwart lager ligt vergeleken met typische koelsystemen. Bedrijven melden een energiebesparing van 30% op koelenergiegebruik wanneer HVLS-ventilatoren worden geïntegreerd in hun klimaatregelsystemen.

Kan het installeren van HVLS-ventilatoren de productiviteit en comfort van werknemers verbeteren?

Ja, door de verbetering van de luchtcirculatie en het behoud van een constante temperatuur verbeteren HVLS-fans het thermisch comfort, wat direct invloed heeft op de productiviteit. Studies tonen aan dat de productiviteit toeneemt, met opvallende verlagingen van vermoeidheid en fouten door warmte.

Wat is de typische terugverdientijd (ROI) voor HVLS-fans?

De typische terugverdientijd voor de installatie van HVLS-fans in industriële omgevingen ligt tussen de 14 en 26 maanden. Na deze periode kunnen voortdurende bedrijfskosten leiden tot aanzienlijke jaarlijkse besparingen en een aanzienlijke ROI gedurende de levensduur van de fans.

Inhoudsopgave

- Hoe hoogwaardige plafondventilatoren de temperatuurregeling in werkplaatsen verbeteren

-

Energie-efficiëntie en kostenbesparingen met HVLS-plafondventilatoren

- HVLS-ventilatoren versus traditionele HVAC: vergelijking van energieverbruik en efficiëntie

- Data-inzicht: 30% lagere koelenergiegebruik in magazijnomgevingen

- Vermindering van de belasting op HVAC-systemen en langdurige operationele kosten

- ROI-analyse: Teruggewinningsperiode voor HVLS-ventilatorinstallaties in industriële omgevingen

- Verbetering van luchtkwaliteit en werknemerscomfort in industriële werkplaatsen

- Optimale plaatsing en afmeting voor maximale effectiviteit van plafondventilatoren

- Slimme installatie, onderhoud en duurzaamheid

-

Veelgestelde vragen

- Wat zijn HVLS-plafondventilatoren en hoe verschillen ze van gewone plafondventilatoren?

- Hoeveel kunnen HVLS-plafondventilatoren besparen op energiekosten?

- Kan het installeren van HVLS-ventilatoren de productiviteit en comfort van werknemers verbeteren?

- Wat is de typische terugverdientijd (ROI) voor HVLS-fans?

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

HY

HY

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

KK

KK

KY

KY

ONLINE

ONLINE