Energy Efficiency and Operational Cost Savings

Reducing Energy Consumption Rates with Industrial Fans

Industrial fans play a crucial role in enhancing energy efficiency by optimizing airflow patterns, which contributes to a more efficient cooling system. These fans improve air circulation and can significantly lower cooling costs. Research indicates that using industrial ceiling fans can reduce cooling expenses by up to 30%, depending on the facility's size and layout. Additionally, by operating at lower speeds, industrial fans can effectively move air without the excessive energy demand that traditional HVAC systems entail. This reduction in energy consumption directly translates into operational cost savings, making industrial fans an economically sound choice for businesses looking to optimize their facilities.

Long-Term Savings vs. HVAC Systems

When considering long-term savings, industrial ceiling fans often emerge as a more favorable option compared to HVAC systems. While the initial investment for industrial fans may be lower, the extended benefits are substantial due to reduced maintenance and operational costs. A study published by the U.S. Department of Energy highlights that integrating industrial fans with existing HVAC systems can yield efficiency improvements of approximately 15-20%. This synergy between fans and HVAC systems enhances airflow and reduces energy consumption, offering significant cost advantages over time. Evaluating the total cost of ownership (TCO) underscores the economic benefits, revealing that industrial fans can deliver financial savings throughout a facility's lifecycle.

Thermal Management Benefits for Factories

Effective thermal management is essential in maintaining consistent temperature levels across large warehouse and factory spaces. Industrial fans play a vital role in achieving this by ensuring uniform air distribution, which is critical for environments that handle perishable goods. By employing industrial fans, facilities can mitigate spoilage risks in temperature-sensitive areas, thus reducing waste. Additionally, optimizing thermal management contributes to improved employee comfort and productivity. Various studies have demonstrated that better thermal conditions lead to reduced absenteeism rates linked to heat stress, thereby boosting overall workplace efficiency. Industrial fans prove indispensable in creating a comfortable and productive environment within factories and warehouses.

Industrial Ceiling Fans vs. Traditional Cooling Methods

Ceiling Fans vs. Pedestal Fans for Large Spaces

When it comes to large spaces, industrial ceiling fans offer superior air circulation compared to pedestal fans. This advantage is mainly due to their fixed installation and larger blade span, which enables them to distribute air more evenly across extensive areas. Ceiling fans cover larger areas at a consistent height, something pedestal fans struggle with due to their mobility limits and height adjustments. Pedestal fans, while flexible, can only provide localized airflow that isn’t as effective for comprehensive cooling. In contrast, ceiling fans create a defined cooling effect that enhances comfort levels across various seating arrangements, making them particularly effective for manufacturing plants and warehouses.

Destratification: Balancing Heat in Industrial Settings

Effective heat management in industrial spaces is crucial, and destratification plays a key role in achieving this balance. Destratification involves redistributing air layers to prevent heat accumulation at the ceiling level, which can be accomplished through industrial fans. By managing temperature gradients effectively, facilities can achieve significant energy savings and improved equipment performance. Case studies have revealed that factories employing destratification techniques with ceiling fans report energy cost reductions of up to 20%. This method not only reduces energy consumption but also enhances overall workplace conditions by maintaining a more consistent temperature distribution.

Cost-Effectiveness Compared to Air Conditioning

The cost-effectiveness of industrial ceiling fans is notably superior to traditional air conditioning systems. These fans operate at a fraction of the cost, providing an eco-friendly and budget-conscious alternative for cooling large areas. Cost analyses demonstrate that industrial fans consume approximately 80% less energy than traditional air conditioning units while enhancing comfort levels within factories. Furthermore, the lower demand for maintenance associated with ceiling fans contributes to overall savings, as they often require less frequent servicing than their air conditioning counterparts. Industrial fans represent a wise choice for businesses aiming to reduce operational costs without compromising on staff comfort and productivity.

Key Features of High-Performance Industrial Fans

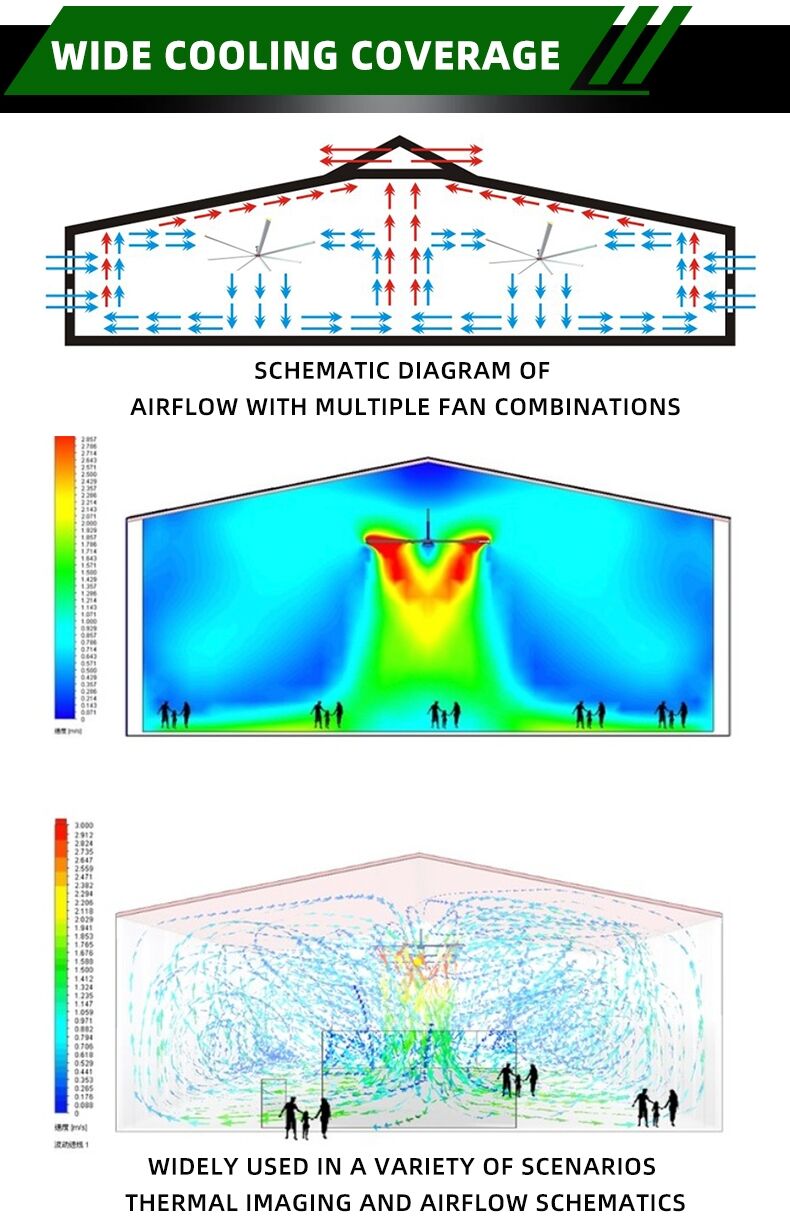

Axial Airflow Capacity and Coverage

High-performance industrial fans leverage an axial airflow design to efficiently move large volumes of air while maintaining low noise levels. This design is particularly effective as reports suggest these fans can cover an area of up to 20,000 square feet, making them ideal for expansive industrial applications. Furthermore, the capability to customize airflow direction enhances their coverage, providing tailored airflow solutions that can meet specific environmental needs. This adaptability ensures that the fans can be optimized for various settings, offering versatility in managing industrial climates.

Durability in Harsh Environments

Industrial fans are engineered using robust materials to endure extreme conditions like high temperatures, dust, and moisture typical in industrial environments. Many high-performance fans carry certifications from recognized standards like UL or CE, signifying their reliable operation under adverse conditions. Feedback from the industry often highlights durability as a vital element in reducing the frequency of replacements and ensuring sustained operation over time. This focus on durability means businesses can count on these fans to perform consistently, even in the harshest settings.

Advanced Motor Technology (EC/BLDC)

Incorporating EC (Electronically Commutated) and BLDC (Brushless Direct Current) motors into industrial fans significantly boosts efficiency. These motors offer precise speed control which enhances operational flexibility and energy savings, making them well-suited for dynamic industrial environments. Industry experts estimate that fans equipped with this advanced motor technology can reduce energy consumption by 30-50% compared to traditional motors, representing substantial long-term savings. This combination of precision and efficiency underscores the value of advanced motors in modern industrial fan technology.

Optimizing Airflow and Comfort in Factories

Noise Reduction Strategies for Productivity

Implementing effective noise reduction strategies in factories is essential for enhancing workplace comfort and boosting productivity levels. High noise levels can be distracting and lead to decreased focus among employees, which directly impacts output. To combat this, factories can integrate technologies such as vibration isolation pads or sound-dampening materials into fan installations. These measures help to minimize noise pollution, creating a quieter work environment. Research supports this approach, indicating that unaddressed noise can reduce productivity by as much as 15%. Reducing noise not only improves employee well-being but also contributes to a more efficient production process.

Zoning and Air Circulation Best Practices

Adopting zoning and air circulation best practices is key to optimizing airflow in factories. By delineating specific areas according to operational requirements or equipment locations, factories can target airflow more effectively. Placement and speed adjustments of industrial fans enhance thermal comfort for workers, maintaining optimal working conditions throughout the day. When implemented successfully, these strategies can lead to improved energy efficiency ratings. Enhanced air circulation not only benefits the well-being of employees but also results in significant operational cost savings, creating a more sustainable environment for manufacturing activities.

Installation Considerations for Maximum Efficiency

For industrial fans to achieve maximum efficiency, proper installation is paramount. This includes paying attention to the height, angle, and spacing to create optimal airflow patterns. Understanding airflow dynamics is crucial, as it prevents issues like turbulence or stagnant zones, which can compromise efficiency. Receiving guidance from industry professionals during installation helps to ensure these considerations are met, leading to expected energy savings and comfort improvements. Properly installed fans not only contribute to airflow efficiency but also enhance the overall performance and longevity of the equipment in industrial settings.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

HY

HY

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

KK

KK

KY

KY

ONLINE

ONLINE