How HVLS Fans Maximize Air Coverage with Minimal Energy Consumption

Understanding the aerodynamics of HVLS fan airflow distribution

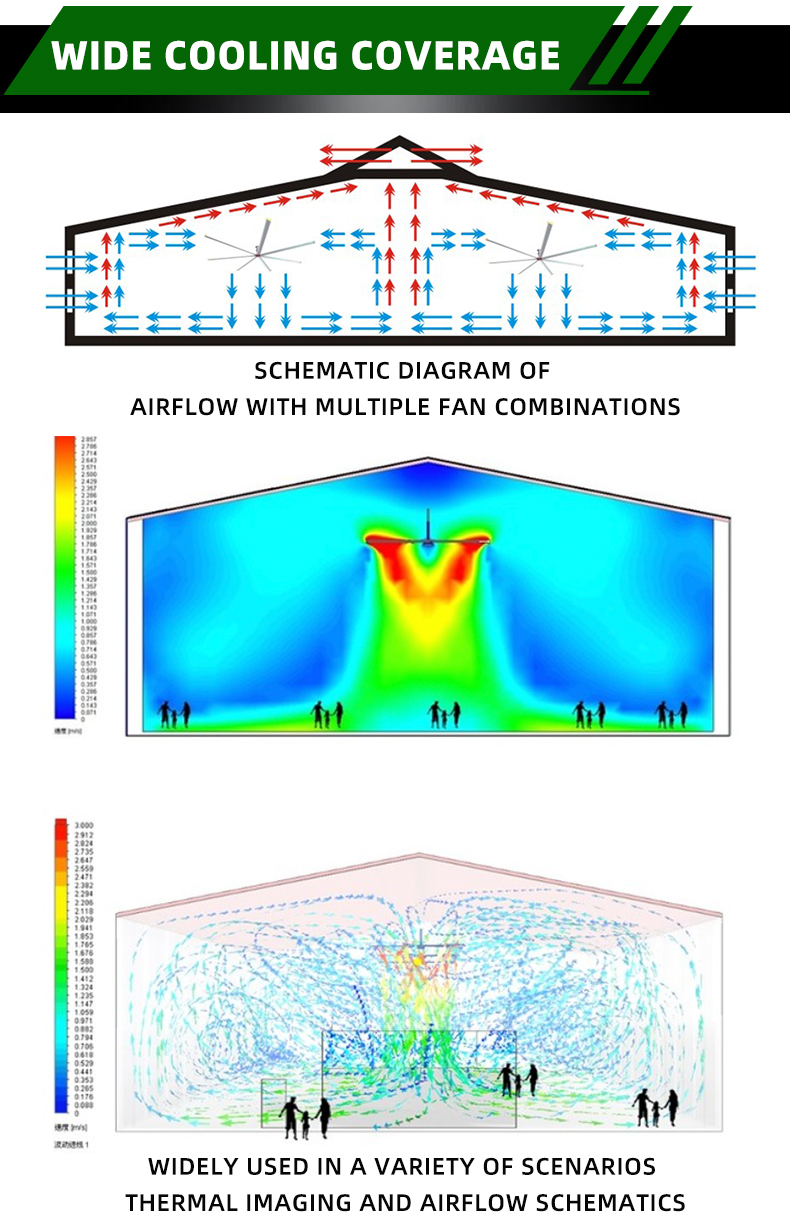

HVLS fans move air efficiently thanks to their laminar airflow system. These big fans have blades ranging from 7 to 24 feet in diameter that push air downward in a straight column which then spreads out across factory floors. What makes them special is how far they can reach - sometimes affecting airflow as much as 30 to 40 feet past where the blades actually are, while keeping wind speeds under 5 miles per hour so people don't feel uncomfortable. The real magic happens when looking at performance metrics. At only 50 to 150 revolutions per minute, these fans can handle over quarter million cubic feet of air per minute. This means they clear out temperature layers in warehouses and manufacturing plants roughly three times quicker than standard axial fans do, making for better climate control throughout large spaces.

The role of large diameter blades in energy-efficient air circulation

Blade length directly affects efficiency due to fundamental physical laws:

- Doubling blade length quadruples coverage area (square function)

- Halving rotational speed reduces power consumption by 87.5% (cube function)

As a result, a 24-foot HVLS fan delivers 22,000 CFM per watt—47 times more efficient than 36-inch high-speed fans producing only 470 CFM per watt under equivalent energy input.

Why 1200m² is the optimal coverage range for a single 1.5KW HVLS fan

Manufacturer testing shows 1.5KW HVLS fans achieve peak performance at 1200m² coverage:

| Factor | Specification | Impact |

|---|---|---|

| Blade Diameter | 7.3m | Optimizes torque requirements |

| Airflow Velocity | 0.3—2.0 m/s | Balances coverage & comfort |

| Power Curve | 70% rated load operation | Minimizes kWh/m² consumption |

A 2023 airflow efficiency study found this configuration maintains over 80% airflow uniformity while consuming less than 0.9 kWh during continuous operation.

Performance comparison: HVLS fan vs. traditional industrial fans (CFM/Watt)

HVLS technology reduces cooling energy demand by 37% compared to conventional systems:

- HVLS Fan (1.5KW): 158 CFM/watt @ 1200m²

- High-Speed Fans (8x400W): 94 CFM/watt @ 800m²

- AC Ventilation Systems: 28 CFM/watt @ 1200m²

This advantage comes from whole-space air mixing rather than localized turbulence, significantly improving thermodynamic efficiency.

Case study: Effective warehouse cooling in Guangdong using a 1.5KW HVLS fan

An 8,000m² logistics center near Guangzhou deployed six 1.5KW HVLS units to address 6.5°C temperature stratification:

- Air Turnover: Increased from 0.8 to 3.2 exchanges/hour

- Peak Cooling Load: Reduced by 18.7% (34 ⟶ 28 kW)

- Energy Cost: Saved $940/month versus previous axial fan system

Work productivity rose 11%, and heat-related equipment failures dropped by 26% during summer operations.

Energy Efficiency Analysis of 1.5KW HVLS Fan Operation

Power Consumption Under Continuous Operation

High Volume Low Speed (HVLS) fans bring together efficient motors and specially shaped blades to run effectively at around 1.5KW power levels. According to various industry studies, these systems typically draw less than 1.0 kWh each hour, which means they can run continuously without breaking the bank on electricity bills. Looking at monthly consumption, most facilities see around 720 kWh used overall, roughly what it would take to power about fifteen regular 48W industrial fans instead. What makes HVLS fans stand out is their massive blade size ranging from seven to twenty-four meters across. These big blades push way more air volume for every watt consumed compared to traditional ceiling fans, delivering airflow efficiency improvements of as much as three times better in many cases.

Monthly Electricity Savings in Manufacturing Facilities Using HVLS Fans

Facilities benefit from predictable operating costs thanks to consistent 1.0 kWh/hour consumption. A 2024 analysis of automotive assembly plants revealed 19—27% reductions in cooling-related energy bills after switching to HVLS fans, all while maintaining OSHA-compliant airflow velocities of 0.3—1.5 m/s across workstations.

Real-World Applications of HVLS Fans in Large Industrial and Agricultural Spaces

HVLS Fan Performance in Logistics Centers: Air Turnover Rate and Worker Comfort

In modern logistics warehouses, many operators are turning to 1.5KW high volume low speed fans for better air circulation. These massive fans can move around 228,000 cubic feet of air per minute across spaces as large as 1200 square meters. The result? A much more even distribution of air throughout the facility that cuts down on those annoying hot spots by about 8 degrees Celsius according to recent climate studies from warehouse environments in 2023. Take for example a warehouse operation in Guangdong province where staff noticed their productivity jumped nearly 18% after installing these fans, largely because workers were no longer dealing with uncomfortable temperature extremes. Industry reports from last year show another benefit too: buildings equipped with HVLS systems put significantly less stress on their heating ventilation and air conditioning units, cutting overall system strain by roughly 40% when compared against older style industrial fan setups.

Agricultural Use Cases: Livestock Barns and Poultry Farms

HVLS fans have been making waves in agriculture, particularly for cutting down ammonia levels around 30 percent in poultry farms thanks to their constant movement of air. Research from the University of Nebraska back in 2022 found something interesting too. They noticed that dairy barns equipped with these large fans kept things at about 65% humidity all year long, which seems to go hand in hand with roughly 22% fewer cases of heat stress among animals. For pig farmers, mixing HVLS systems with regular ventilation methods has led to better results as well. Many report seeing anywhere from 15 to 20% improvement when it comes to how efficiently pigs convert feed into weight gain.

Key Technological Innovations Driving Modern HVLS Fan Efficiency

Modern HVLS fans achieve unprecedented efficiency through three core advancements, enabling industrial facilities to maintain ideal airflow while cutting energy costs by up to 40% (Energy Logic 2024).

Advancements in Motor Efficiency for HVLS Fan Systems

Permanent magnet synchronous motors (PMSM) now reach 92% energy conversion efficiency—15% higher than older induction motors. These brushless designs eliminate friction losses and provide steady torque at low RPM, supporting reliable 24/7 operation at 1.5KW. Field tests show PMSM-equipped fans reduce annual maintenance costs by $3,200 per unit (HVAC Tech Journal 2024).

Smart Controls Integration: How IoT Enhances HVLS Fan Functionality

IoT-enabled sensors adjust fan speed based on real-time temperature and occupancy data. A 2024 Industrial IoT Report found smart-controlled HVLS systems delivered 28% greater energy savings than manually operated units. Wireless modules allow centralized management via building automation systems, optimizing airflow across entire facilities.

Material Science: Lightweight Yet Durable Blades in HVLS Fan Construction

Aerospace-grade carbon-fiber reinforced polymer (CFRP) blades weigh 60% less than aluminum while maintaining structural integrity at 7.2 meters. This reduction lowers motor load by 22%, helping sustain the 1.5KW power benchmark. Stress tests confirm CFRP blades endure 150 million rotational cycles without deformation—equivalent to 18 years of continuous operation (Advanced Materials Research 2024).

FAQ Section

What is the primary benefit of using HVLS fans?

The primary benefit of using HVLS fans is their ability to maximize air coverage across large spaces with minimal energy consumption, significantly improving climate control and energy efficiency.

How do HVLS fans compare with traditional industrial fans in terms of efficiency?

HVLS fans are substantially more efficient than traditional industrial fans, delivering up to 47 times more CFM per watt, thus reducing energy demand and cost.

What makes HVLS fans suitable for agricultural uses?

In agricultural settings, HVLS fans reduce ammonia levels, maintain optimal humidity, and decrease heat stress among animals, thereby enhancing productivity and comfort.

Can HVLS fans be integrated with existing building systems?

Yes, HVLS fans can be integrated with building automation systems through IoT-enabled smart controls, optimizing air circulation and energy use based on real-time data.

Table of Contents

-

How HVLS Fans Maximize Air Coverage with Minimal Energy Consumption

- Understanding the aerodynamics of HVLS fan airflow distribution

- The role of large diameter blades in energy-efficient air circulation

- Why 1200m² is the optimal coverage range for a single 1.5KW HVLS fan

- Performance comparison: HVLS fan vs. traditional industrial fans (CFM/Watt)

- Case study: Effective warehouse cooling in Guangdong using a 1.5KW HVLS fan

- Energy Efficiency Analysis of 1.5KW HVLS Fan Operation

- Real-World Applications of HVLS Fans in Large Industrial and Agricultural Spaces

- Key Technological Innovations Driving Modern HVLS Fan Efficiency

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

HY

HY

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

KK

KK

KY

KY

ONLINE

ONLINE