What Determines the Coverage Area of a 7.2m Big Fan?

Key Factors: Fan Diameter, Blade Span, and Motor Power

When looking at how far a 7.2 meter fan can reach, there are basically three things that matter most: the size of the blades, how efficient the motor works, and the strength of its rotation. Bigger industrial fans generally spread air over much larger areas. Take a 7.3m fan as an example—it should be able to move air throughout around 1,200 to 2,000 square meters in open environments. The shape of the blades makes a real difference too. Fans with specially designed blades cut down on turbulence problems without using extra electricity. Most fans in this size range have motors between 1.5 and 3 kilowatts. These motors provide just enough power to keep the fan spinning slowly but steadily, which is exactly what's needed to push air across large spaces effectively.

The Relationship Between Big Fan Size and Square Footage Covered

The bigger the fan blades, the more ground they cover, but there's no straight line between size and performance. When we double the blade length, the area it sweeps over goes up four times, yet the motor has to work eight times harder just to keep the same air speed going. That's why those 7.2 meter fans often manage to reach 15 to 25 percent more floor space compared to their 6 meter counterparts, despite having exactly the same motor inside. Warehouse managers who stick with standard 7 meter units generally find their cooling zones stretch anywhere from 1,500 square feet all the way up to 4,500 square feet. Of course, this depends heavily on how high the ceilings are and which way the air actually flows through the space.

Theoretical vs Real-World Coverage: Bridging the Gap in Industrial Applications

Most manufacturers figure out coverage based on perfect scenarios (like empty rooms with 8 to 10 meter ceilings), but what actually happens on site tends to be about 60 to 70% of what's promised. Recent studies from 2023 showed something interesting too. Those warehouse columns, all those boxes stacked everywhere, plus the HVAC ducts? They cut down airflow effectiveness somewhere between 18% and 34% in factories and warehouses. If good performance matters, most experienced engineers suggest cutting theoretical numbers by around 30% when laying out fans. Take a 7.2 meter unit rated for 5,000 square feet as an example. In reality, it probably won't cover more than 3,500 square feet if there are obstacles in the way.

Typical Coverage and Application of 7.2m HVLS Fans in Large Spaces

Average coverage area of a 7.2-meter big fan in warehouses and factories

Tests have shown that 7.2 meter high volume low speed fans can cover areas ranging from about 12,900 to 21,500 square feet in warehouses. Some top performers actually manage around 22,000 square feet when everything is set up just right, as noted in recent airflow studies from last year. Looking at actual performance numbers across different facilities, we find that coverage really depends on how high those ceilings are – best results come when they're between 20 and 30 feet tall. Also important is making sure there aren't too many obstacles getting in the way, such as rows of shelves or big machines scattered throughout the space.

Performance in commercial spaces: Air distribution in gyms, hangars, and distribution centers

Large industrial spaces like aircraft hangars and warehouses see significant improvements when using those 7.2 meter diameter fans. These massive units cut down on temperature layers within the space by about 8 to 10 degrees Fahrenheit or roughly 4 to 5 Celsius thanks to their broad, gentle airflow movement across the area. For gyms specifically, getting around 15 to 20 complete air exchanges each hour makes all the difference in controlling moisture levels near workout machines where sweat tends to accumulate. What's really impressive is how these fans operate at just 1 to 2 revolutions per minute yet still manage to push over 300 thousand cubic feet of air every single minute without creating uncomfortable drafts or wind chill effects for people working out or moving around inside these facilities.

Do manufacturers overstate big fan coverage claims? A critical analysis

Field tests in automotive plants show actual coverage areas often trail theoretical claims by 15–30% due to common obstructions like conveyor systems and storage racks. While manufacturers cite 20,000+ sq ft coverage for 7.2m models, thermal mapping in food warehouses reveals effective temperature control rarely exceeds 16,000 sq ft without supplemental fans.

Environmental and Structural Factors That Impact Big Fan Efficiency

How ceiling height influences airflow reach and circulation

The height of the ceiling plays a major role in how well a large 7.2 meter fan can spread air throughout a space. Most industrial fans work best when mounted in buildings where the ceiling is between 8 and 12 meters high. At these heights, the fan creates nice horizontal air movement that really improves overall circulation in the area. But things get tricky in very tall spaces over 15 meters. The air just doesn't maintain enough momentum to reach down to floor level properly. On the flip side, installing these fans in rooms with ceilings lower than 6 meters often leads to messy downward drafts that disrupt comfort. As a general rule of thumb, each additional meter added to ceiling height results in around a 12 to 15 percent drop in airflow speed. This means technicians need to carefully adjust both the angle of the blades and the strength of the motor to compensate for these losses.

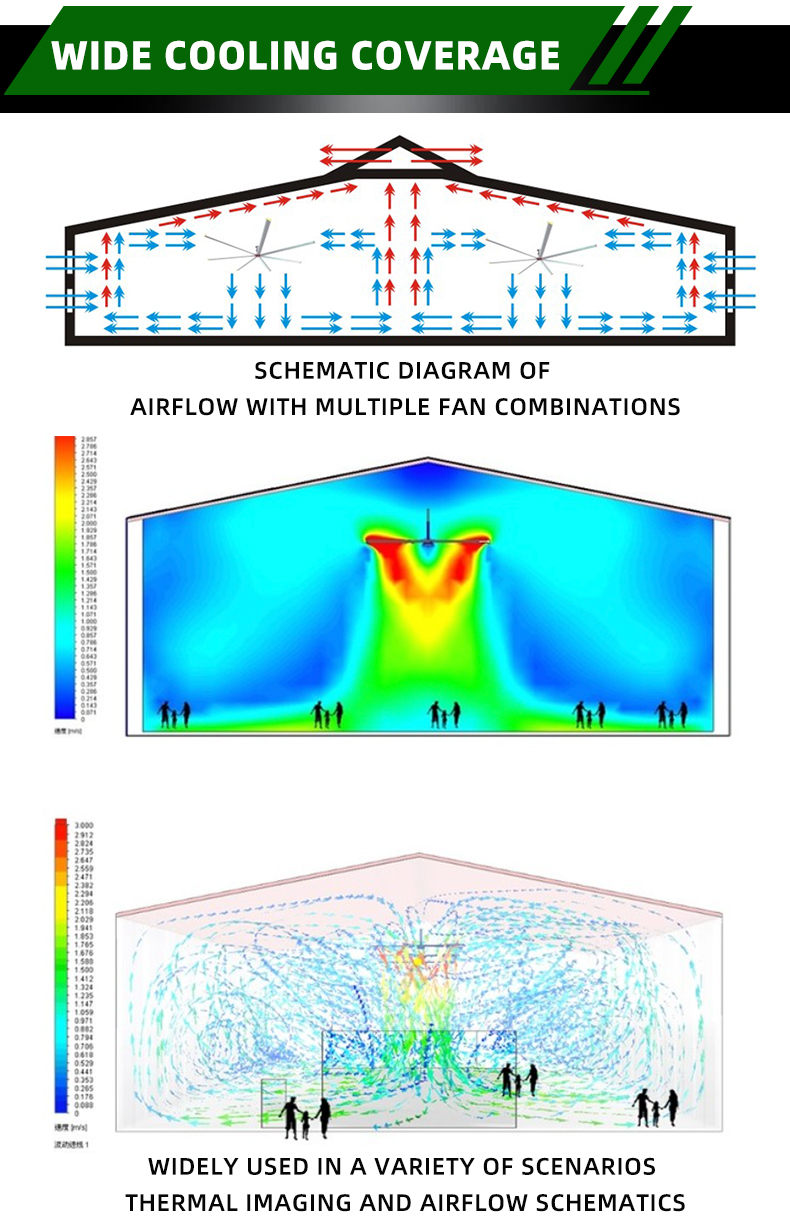

Optimal spacing between HVLS fans for seamless coverage

When installing several 7.2 meter industrial fans, it's generally recommended to keep them spaced at least 1.5 to 1.8 times their diameter apart to avoid problems with air flow interference. Some actual field tests in warehouses showed something interesting though – when fans were positioned so their coverage areas overlapped just right, energy consumption dropped by around 22% compared to having each fan work completely alone. On the flip side, if fans are placed too close together (less than 9 meters apart), there tend to be spots directly underneath where air doesn't circulate properly. And when they're spread out more than 13 meters apart, the middle sections often end up getting very little ventilation at all, which defeats the whole purpose of having multiple units installed.

Building layout, obstructions, and climate conditions affecting performance

When storage racks, machines, and wall structures get in the way, they mess up how air flows around a space. This can cut down on the actual coverage area for cooling systems by anywhere from 18 to 35 percent in complicated factory setups. Studies indicate that in hot desert areas where temperatures hit over 40 degrees Celsius, fans just don't work as well as they do in cooler regions, with cooling effectiveness dropping about 30%. Meanwhile along coastlines, salt in the air causes corrosion problems that slowly eat away at fan blades, cutting their efficiency by roughly 1.2% every year. Getting serious about these factors means thinking carefully about where equipment goes and adapting to local conditions. Doing so helps maintain reliable performance from large industrial fans no matter what kind of environment they're operating in.

Matching Airflow Demand with Big Fan Output Using CFM and Air Change Rate

Understanding CFM: How Cubic Feet per Minute Define Industrial Fan Performance

CFM stands for Cubic Feet per Minute, basically telling us how much air a 7.2 meter fan pushes around each minute. Most manufacturers love touting their max CFM numbers, but what really counts is getting the right amount of airflow for whatever space needs cooling. Take a fan claiming 150,000 CFM performance - it won't work so well in rooms where ceilings are under 6 meters high because the air just slams down too hard. There's also this interesting connection between blade angle and actual airflow output. Change those blades by just 5 degrees and suddenly we're looking at anywhere from 12 to 18 percent difference in airflow, all without touching the motor speed. That kind of sensitivity makes a big difference when trying to balance comfort against energy costs in commercial settings.

Calculating Required Airflow Based on Room Volume and Air Changes Per Hour

To match fan capacity with operational needs, use this formula:

| Factor | Formula | Example (Warehouse) |

|---|---|---|

| Room Volume (ft³) | Length × Width × Height | 200ft × 150ft × 20ft = 600,000 ft³ |

| Air Changes/Hour (ACH) | Industry standard: 6-30* | 8 ACH for mixed-use storage |

| Required CFM | (Volume × ACH) ÷ 60 | (600,000 × 8) ÷ 60 = 80,000 CFM |

*Per ASHRAE ventilation guidelines for industrial environments

Why High CFM Doesn’t Always Mean Better Coverage: The Industry Paradox

Research from 2023 looking at 47 different warehouse setups showed something interesting: when fans were cranked up past their calculated CFM needs by around 40%, temperature consistency across the space only improved by about 7%. What really matters is what happens when there's just too much air moving around. The excess creates these weird turbulence areas where the air basically just spins in circles instead of spreading out properly. That's why many warehouses actually do better with several smaller fans spread throughout the building rather than one big powerful unit. Smaller units can be placed right where they're needed most for specific spots that get too hot or cold. Getting the fan sizes right isn't just about saving money on electricity bills (which typically run about $0.18 per kWh in industrial settings). Workers notice the difference too when temperatures stay within comfortable ranges throughout the day.

FAQ Section

How much area can a 7.2m big fan cover?

The amount of area a 7.2m big fan can cover depends on several factors like blade design, motor efficiency, and environmental conditions. Typically, these fans can cover between 1,500 to 4,500 square feet in practical settings.

What influences the performance of a big fan in a commercial space?

The performance is influenced by the ceiling height, spacing between fans, layout of the building, and local climate conditions. The fan's installation and environmental obstructions also play crucial roles.

Do manufacturers often overestimate big fan coverage area?

Yes, real-world tests often show that actual coverage areas fall 15-30% short of manufacturer claims due to obstructions like machinery and ceiling height limitations.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

HY

HY

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

KK

KK

KY

KY

ONLINE

ONLINE