How Big Fans Enhance Air Circulation in Industrial Spaces

Understanding HVLS Fan Technology and Its Role in Large-Scale Airflow

HVLS fans, those big rotating things we see in warehouses and factories, work differently than regular fans. They're built to push around massive amounts of air through large spaces without guzzling electricity. These giants come in sizes between 8 and 24 feet across, spinning slowly somewhere between 50 to 200 revolutions per minute. The slow movement creates a nice steady airflow instead of the choppy gusts from normal ceiling fans. This matters a lot in places where there's dust floating around or other airborne stuff that needs keeping down. Just one of those 24 foot models can handle an area as big as 20,000 square feet. That means fewer fans overall since it replaces what would otherwise be many small units scattered around. According to some industry reports from last year, companies save roughly 30 percent on their power bills when switching to these larger fans.

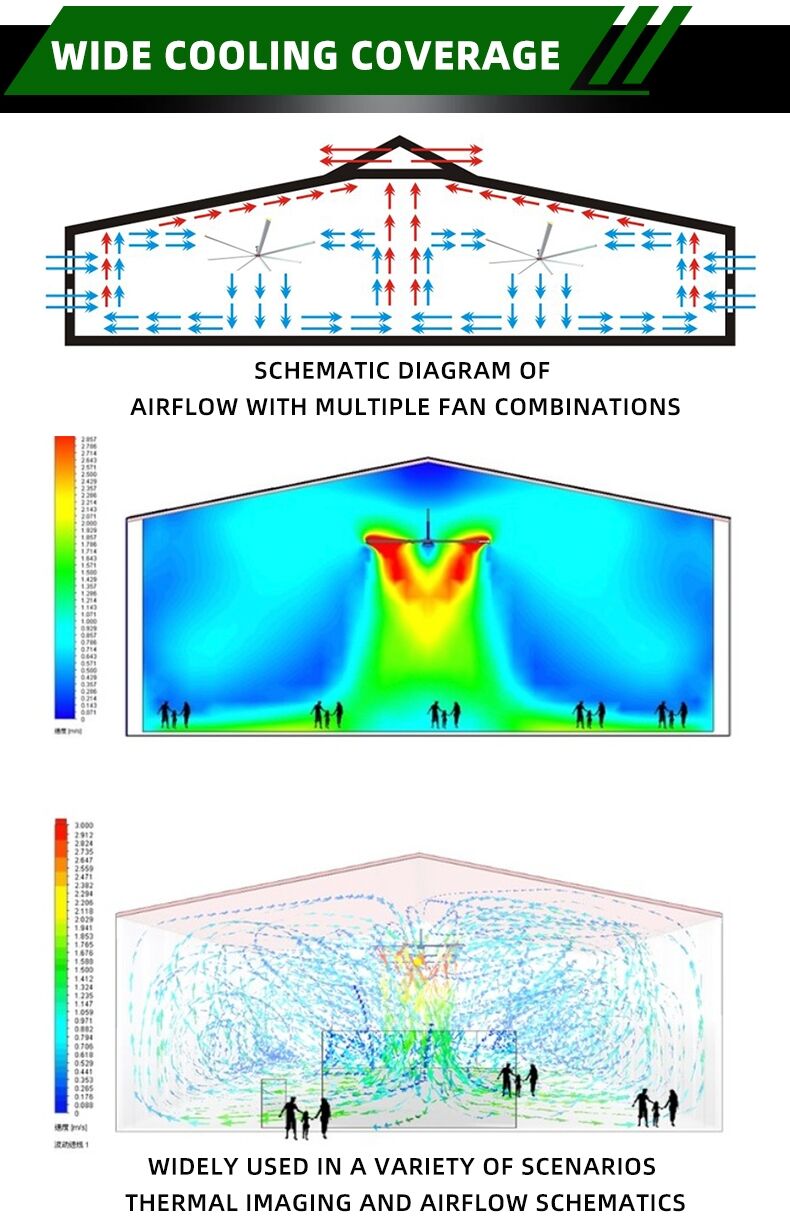

Airflow Dynamics in High-Ceiling Factories and the Impact of Fan Placement

When buildings have those high ceilings over 20 feet tall, hot air naturally climbs upward creating these uncomfortable temperature layers. The result? HVAC systems end up working overtime just to maintain consistent comfort levels throughout the space. Large industrial fans positioned at strategic spots help break down these layers by constantly circulating air between floors and ceilings. According to some studies done back in 2022 (Thermal Comfort Study), placing these fans around 15 to 30 feet off the ground and spacing them roughly two to three times their own width apart can actually make people feel like it's 6 to 8 degrees cooler inside. When combined properly with current heating and cooling systems, this setup not only makes the indoor environment more comfortable but also cuts down on monthly utility bills significantly for facility managers looking to save money while maintaining good working conditions.

Optimizing Air Movement Through Strategic Deployment of Big Fans

Getting the most out of industrial fans means matching them properly to how buildings are laid out and what kind of air movement is needed throughout the space. For facilities with open floor plans, putting fans in central locations works best for spreading airflow evenly across the area. But when there are machines or other obstacles blocking paths, positioning fans along walls or edges can actually help push air around these barriers more effectively. Recent research from last year showed some impressive results too. When companies got their fan setups right, they cut down on HVAC system runtime by almost a quarter, which translated into roughly twelve thousand dollars saved every year for each fifty thousand square feet of space. And it gets better during different seasons. Simply changing how fans tilt or spin directions makes a big difference in keeping temperature layers mixed up and workers comfortable all day long, all while using no extra electricity.

Temperature Control and Thermal Destratification with Big Fans

Reducing Thermal Stratification in Large Facilities Using Big Fans

Thermal stratification can create temperature differences of 15–20°F between floor and ceiling in high-bay facilities, leading to energy waste and discomfort. Big fans mitigate this by mixing air layers, reducing vertical temperature gaps by up to 80%.

| Condition | Ceiling Temperature | Floor Temperature | Energy Use |

|---|---|---|---|

| Without Big Fans | 85°F | 65°F | 100% |

| With Big Fans Operating | 75°F | 72°F | 73% |

This destratification allows consistent thermal conditions and reduces HVAC runtime, improving efficiency and comfort.

Energy Savings Through Fan-Induced Air Destratification: A Real-World Case Study

According to a recent report from the Department of Energy in 2023, businesses that installed large industrial fans saw their annual HVAC expenses drop by around 27%. Take for instance an auto manufacturing facility somewhere in the Midwest where they rearranged their fan setup. They managed to turn down thermostats by about 4 degrees Fahrenheit during those sweltering summer months without making workers uncomfortable, which cut down on how long compressors had to run by roughly 22%. Most companies find these fan systems start paying for themselves within just over a year because they need less heating and cooling overall, plus the equipment lasts longer too. The real magic happens when these big fans tackle those pesky hot spots around the building and spread out the conditioned air more evenly, creating a much better balance throughout the space and wasting far less energy in the process.

Energy Efficiency and Return on Investment of Big Fans

HVLS Fans vs. Traditional HVAC: Comparing Energy Consumption in Industrial Settings

High Volume Low Speed (HVLS) fans actually use just about 1/40th as much electricity compared to regular HVAC systems but still manage decent air movement throughout buildings according to recent studies from the Department of Energy. Traditional heating and cooling units tend to turn themselves on and off repeatedly throughout the day, whereas these big ceiling fans run constantly alongside insulation materials inside structures to keep things at a steady temperature level. Some thermal images taken in warehouses show impressive results too. Fans measuring around 24 feet across create between 4 to 7 degrees Fahrenheit of cooling effect even when there's no actual refrigeration system running. That translates into roughly 30 percent less time spent operating expensive HVAC equipment during those sweltering July days when everyone wants their office nice and cool.

| Technology | Avg. Energy Use (kW/hr) | Coverage Area | Maintenance Needs |

|---|---|---|---|

| 24' HVLS Fan | 0.4 | 16,000 sq.ft | Annual bearing inspection |

| 10-Ton HVAC Unit | 16.0 | 12,000 sq.ft | Monthly filter changes |

Evaluating ROI: Cost Savings and Payback Period of Big Fan Installations

The installation price for HVLS fans usually ranges from around four thousand two hundred dollars up to eight thousand five hundred per unit, though most facilities find they recoup their investment anywhere between six months and eighteen months once HVAC load demands decrease. According to research published in the 2024 Manufacturing Facility Report, one plant saved approximately twelve thousand three hundred dollars each year on a space measuring twenty thousand square feet simply by swapping out thirty-four smaller fans for just two HVLS models, cutting energy expenses down nearly ninety-one percent. For businesses looking at retrofits, there are also various tax rebate programs available that help reduce those already impressive payback times by another couple months in many industrial settings.

Big Fans vs. Multiple Small Fans: Efficiency, Coverage, and Operational Costs

A single 24 foot high volume low speed fan can move around 385 thousand cubic feet per minute while only drawing 1.5 kilowatts of power. That beats the heck out of needing 84 little 48 inch fans which would collectively need 1,680 kW for the same area coverage. Switching to these big fans cuts down on electric bills by about three thousand six hundred dollars each year for every group of small fans replaced. Plus there's an added safety bonus too the risk of accidents from those floor mounted units drops by roughly 82 percent according to some OSHA data from last year. And let's not forget about how these HVLS systems create smoother air movement patterns that don't mess with delicate manufacturing operations where even minor turbulence could cause problems.

Optimal Placement and Coverage Design for Maximum Effectiveness

Determining the Number and Spacing of Big Fans Based on Facility Size

Industrial engineers assess ceiling height, floor plan complexity, and airflow requirements (in CFM) to determine fan layout. In a 50,000 sq. ft. facility with 30-foot ceilings, spacing fans 30–40 feet apart creates overlapping airflow patterns that reduce stagnant zones by 67% compared to random placement, according to ventilation studies.

Fan Diameter and Airflow Coverage: Matching Size to Space Requirements

| Facility Height | Recommended Fan Diameter | Coverage Area |

|---|---|---|

| ≤ 15 ft | 8-12 ft | 2,500 sq. ft |

| 15-25 ft | 16-20 ft | 7,000 sq. ft |

| ≥ 25 ft | 24+ ft | 15,000 sq. ft |

Navigating Obstacles and Ensuring Safe Operation in Active Factory Zones

Big fans require 7–10 feet of vertical clearance beneath blades and 3 feet of lateral space from moving equipment. Adjustable tilt (15°–25°) enables airflow redirection around production lines while maintaining OSHA-compliant safety margins. Facilities following these guidelines report 41% fewer ventilation-related maintenance issues.

Big Fans, Air Quality, and Their Impact on Worker Productivity

Improving Indoor Air Quality and Employee Comfort with Consistent Air Circulation

High Volume Low Speed (HVLS) fans really make a difference when it comes to indoor air quality. They tackle those annoying stagnant spots where dust tends to collect, help manage humidity levels, and spread out airborne particles that hang around too long. The constant gentle movement of air creates spaces that just feel better overall for people working there. Buildings that have installed these systems often see their air quality scores jump anywhere from 25% to 30%, plus they get that nice even temperature throughout the space. Another bonus is how these fans can drop the actual felt temperature between four and seven degrees Fahrenheit, which means companies don't need to run their AC units so hard all the time. This translates into real savings on energy bills while still keeping everyone comfortable.

Linking Ventilation, Health, and Productivity in Industrial Work Environments

Good ventilation really makes a difference for workers because it cuts down on heat stress and tiredness. Research indicates productivity goes up around 12 to maybe even 15 percent in factories with decent airflow systems. The right amount of fresh air circulating through the space keeps people comfortable and their lungs happy instead of irritated. Big industrial fans positioned correctly can hit those OSHA standards for air changes while staying quiet enough not to bother anyone working nearby. Factories that map out how air moves across different work areas tend to see better results overall. Safety improves along with how smoothly operations run day to day. That's why thinking about ventilation isn't just about comfort anymore it's become pretty much required if businesses want successful workplaces.

FAQ

What are HVLS fans?

HVLS (High Volume Low Speed) fans are large industrial fans designed to circulate massive volumes of air at low speeds, optimizing airflow in large spaces while minimizing energy consumption.

How do HVLS fans help reduce energy costs?

HVLS fans reduce energy costs by enhancing air circulation, which helps lower the workload on HVAC systems and minimizes heating and cooling demands.

What benefits do HVLS fans provide in high-ceiling factories?

In high-ceiling factories, HVLS fans help break down temperature layers, improve air circulation, and make indoor environments feel cooler, effectively reducing HVAC system runtimes and energy consumption.

How do HVLS fans contribute to indoor air quality?

HVLS fans enhance indoor air quality by effectively circulating air, preventing stagnant pockets where dust and particles might accumulate, leading to improved air quality and worker comfort.

What considerations are necessary for HVLS fan placement in industrial settings?

For effective placement, consider the layout, facility size, ceiling height, and airflow requirements to ensure optimal fan spacing and air coverage.

Table of Contents

- How Big Fans Enhance Air Circulation in Industrial Spaces

- Temperature Control and Thermal Destratification with Big Fans

- Energy Efficiency and Return on Investment of Big Fans

- Optimal Placement and Coverage Design for Maximum Effectiveness

- Big Fans, Air Quality, and Their Impact on Worker Productivity

- FAQ

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

HY

HY

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

KK

KK

KY

KY

ONLINE

ONLINE