The Role of Big Fans in Factory Air Circulation

Understanding Air Stratification Challenges

Air stratification is a common challenge in industrial settings where temperature and density differences cause layers of air to form, leading to uneven heating and cooling. This can affect worker comfort and reduce energy efficiency. In industries, stratification often results in hot spots, especially around machinery, and cooler areas at floor levels. This uneven distribution necessitates the use of big fans, like industrial ceiling fans, to promote uniform temperature distribution across the workspace. Research supports that addressing air stratification can significantly lower energy costs, reducing expenses by up to 30% as it diminishes the need for additional heating or cooling systems.

How Industrial Fans Disrupt Stagnant Air Pockets

Stagnant air pockets can significantly impact a working environment by trapping heat and humidity, making it uncomfortable and less productive for employees. Big fans, including pedestal and industrial fans, are designed to disrupt this stagnation effectively. By creating airflow patterns that push out stagnant air and replace it with fresher, cooler air, these fans enhance overall ventilation. Implementing industrial fans in the workspace leads to measurable improvements in air quality—lowering humidity and temperature levels—and directly boosts productivity by fostering a more comfortable environment for employees.

Types of Industrial Fans for Optimal Airflow

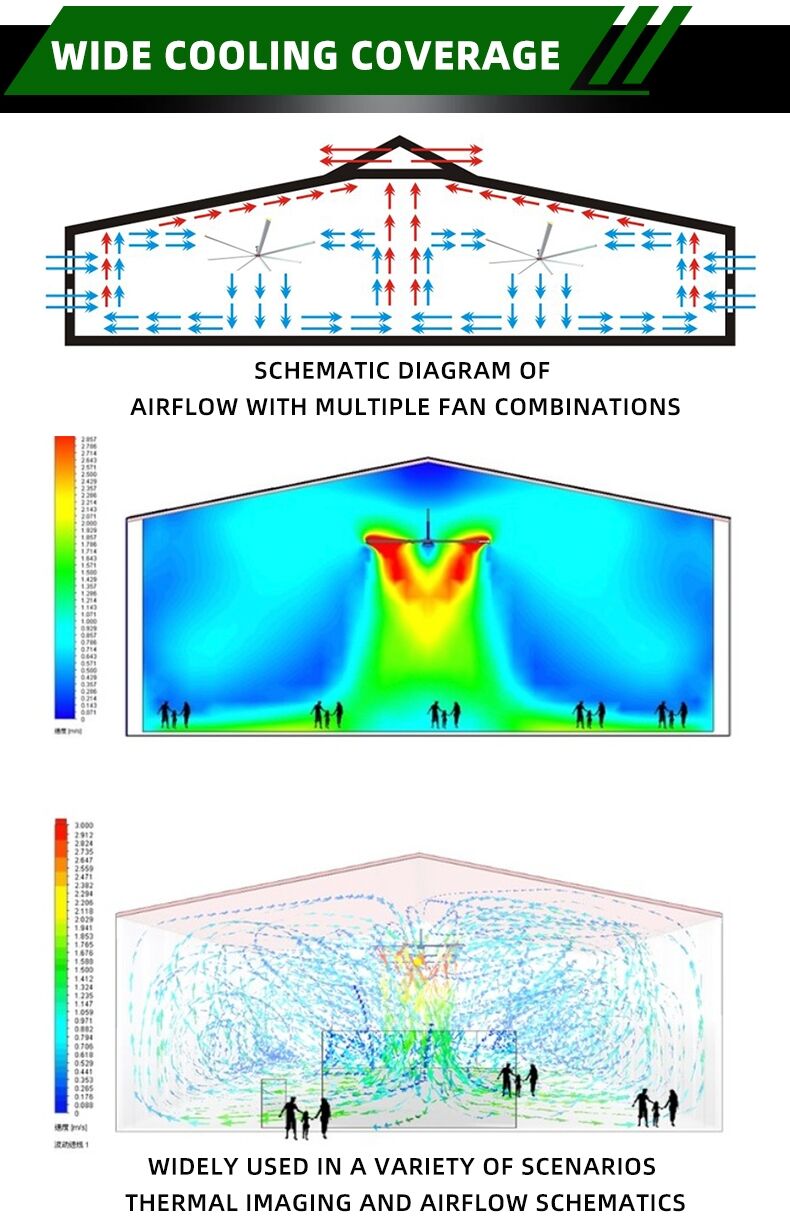

High-Volume Low-Speed (HVLS) Fans for Wide Coverage

High-Volume Low-Speed (HVLS) fans are designed to efficiently move large volumes of air across expansive areas, making them ideal for warehouses and manufacturing facilities. These fans achieve this by operating at lower speeds, allowing them to distribute air up to 20 times more effectively than traditional fans. Such efficiency not only promotes consistent climatic conditions but also significantly reduces energy costs associated with heating and cooling systems. According to industry studies, facilities utilizing HVLS fans can experience energy savings of up to 30%, highlighting their cost-effectiveness in industrial air circulation.

Industrial Ceiling Fans vs. Pedestal Fans: Use Cases

The choice between industrial ceiling fans and pedestal fans depends largely on the specific layout and air circulation needs of a facility. Industrial ceiling fans are typically fixed-mounted and are suitable for large spaces with high ceilings, providing widespread air distribution. On the other hand, pedestal fans offer portability and flexibility, making them ideal for areas requiring specific airflow adjustments. Both types enhance air movement efficiently; however, ceiling fans are better suited for wide, open spaces, while pedestal fans excel in delivering targeted airflow to particular zones, accommodating different workspace environments.

- Industrial Ceiling Fans: Ideal for permanent installations in high-ceiling, wide spaces.

- Pedestal Fans: Portable and adjustable, suited for targeted airflow in specific areas.

Wall-Mounted Fans for Targeted Ventilation

Wall-mounted fans present an effective solution for spaces where floor space is limited but adequate air circulation is essential. These fans are particularly useful in smaller factories or workshops, where they can be strategically placed to direct airflow to target areas that require ventilation. By positioning wall-mounted fans to focus on crucial zones, these devices can enhance overall air quality and improve cooling comfort for employees working in confined and enclosed spaces. Their ability to concentrate airflow makes them a valuable asset in delivering efficient ventilation without compromising on space.

Strategic Placement of Industrial Fans

Calculating Fan Density per Square Footage

The first step in strategically placing industrial fans is calculating the appropriate fan density for your space. This involves determining the volume of air required to effectively ventilate the area, typically measured in cubic feet per minute (CFM). A general guideline suggests estimating 2-3 CFM per square foot in industrial settings. This figure can be adjusted based on specific environmental factors such as heat generation and building layout. By using precise calculations, we can ensure that fans are placed adequately to optimize air movement and avoid excessive energy consumption across the facility.

Avoiding Obstructions for Uninterrupted Airflow

Strategically positioning fans also means avoiding obstructions that could impede air movement. Objects like machinery, shelves, or equipment can reduce a fan's effectiveness and must be accounted for during installation. Conducting thorough pre-installation assessments helps identify these potential blockages, ensuring that air pathways remain clear. By maintaining unobstructed airflow paths, we can significantly improve thermal comfort and air quality, underscoring the necessity of thoughtful fan placement for efficient ventilation.

Seasonal Adjustments for Summer/Winter Efficiency

To maximize the efficiency of industrial fans throughout the year, seasonal adjustments may be necessary. This often involves altering fan direction and speed to match changing temperature needs: counterclockwise for cooling in the summer and clockwise for warming in the winter. In colder months, industrial fans can help push the warm air that accumulates near the ceiling back down, ensuring a comfortable temperature at the occupancy level. Implementing these seasonal strategies not only enhances energy efficiency but also contributes to reduced heating and cooling expenditures.

Best Practices for Maintaining Air Circulation

Combining Fans with HVAC Systems

Integrating industrial fans with HVAC systems creates a more balanced air exchange, resulting in improved indoor air quality and energy efficiency. By circulating and conditioning air effectively, this combination addresses contaminants like dust and allergens, ensuring a cleaner environment. Expert studies suggest that such integrated systems can lower operational costs while boosting employee health and productivity. Enhanced airflow reduces the reliance on HVAC systems alone, leading to decreased energy usage and prolonged equipment life. Ultimately, this synergy not only protects air quality but also promotes a healthier workplace atmosphere.

Routine Maintenance for Peak Performance

Regular maintenance checks are essential for the efficient operation of industrial fans. This involves cleaning blades, checking motor performance, and inspecting electrical connections. Setting up a consistent maintenance schedule allows for early identification of potential issues, ensuring that fans remain a reliable component of air circulation systems. Data from the industry indicates that well-maintained fans can improve energy efficiency by up to 15%, resulting in significant cost savings. Routine upkeep not only extends the lifespan of the equipment but also optimizes airflow, contributing to enhanced indoor environmental quality.

Energy Efficiency Monitoring Techniques

Implementing energy monitoring tools can provide crucial insights into fan operations, allowing facilities to analyze performance data and make necessary adjustments. By identifying peak usage times and optimizing fan schedules, substantial energy savings can be achieved, reinforcing best practices in operational efficiency. Research shows that effective monitoring can decrease energy consumption by an average of 10-20%. This proactive approach not only supports sustainable practices but also aligns with cost management strategies, ensuring energy efficiency in air circulation tasks.

Additional Tips for Enhanced Air Quality

Sealing Entry Points Against External Contaminants

Identifying and sealing gaps, cracks, and other entry points that allow pollutants or dust to infiltrate the facility is essential for maintaining air quality. These can undermine the effectiveness of any air circulation efforts, leading to a compromised atmosphere inside. When entry points are tightly sealed, the air environment becomes more controlled, reducing the load on filtration systems tasked with maintaining a healthy atmosphere. There is statistical evidence showing that environments with well-sealed entry points can significantly reduce particulate matter, thus enhancing overall air quality. By minimizing the risk of unwanted pollutants, we not only ensure cleaner air but also promote healthier indoor environments.

Using Air Quality Sensors with Fan Systems

Incorporating air quality sensors with fan systems allows for real-time monitoring of pollutants and particulates, which is crucial for optimal air quality management. This integration provides valuable data that enables timely adjustments in fan operations, making environmental control more effective. Sensors can trigger fans to operate under specific conditions, ensuring enhanced air quality and healthier indoor spaces. Studies have shown that intelligent systems combining air quality monitoring and fan use effectively lower concentrations of harmful pollutants. With these advanced tools, facilities can maintain a cleaner atmosphere, reducing potential health hazards and boosting productivity through better indoor air conditions.

Table of Contents

- The Role of Big Fans in Factory Air Circulation

- Understanding Air Stratification Challenges

- How Industrial Fans Disrupt Stagnant Air Pockets

- Types of Industrial Fans for Optimal Airflow

- Strategic Placement of Industrial Fans

- Best Practices for Maintaining Air Circulation

- Additional Tips for Enhanced Air Quality

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

HY

HY

AZ

AZ

KA

KA

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

KK

KK

KY

KY

ONLINE

ONLINE